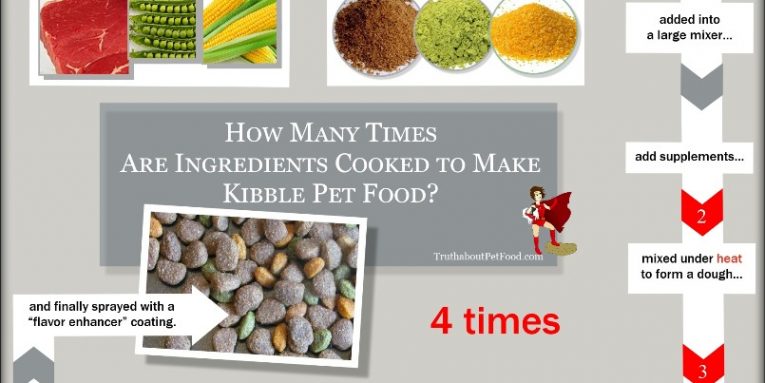

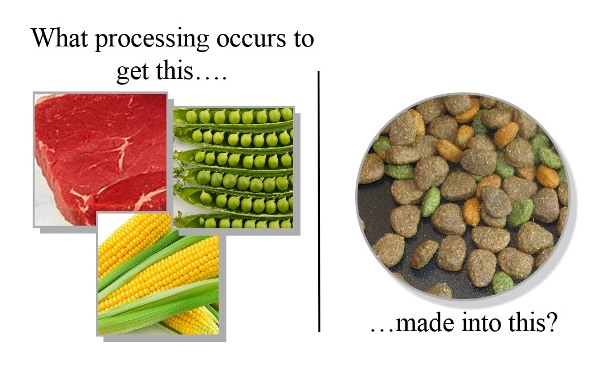

Do you know the producing involved in the manufacturing connected with kibble pet food? How frequently are the ingredients grilled? The answer might astonish you.

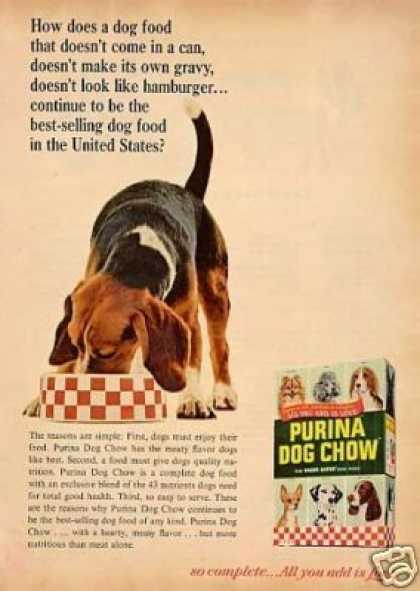

Pet food kibble was invented within 1956 by Purina; which is Purina was the first to provide an extruded kibble pet food invariably are made today. Ahead of kibble, the greatest most of pet food sold in the nation was canned commercial dog food. But shortly after Purina’s introduction of Purina Dog Chow, (within two years), kibble became the leading style of dog food in the US.

And that level of popularity has continued-

Statistics for 2016, Anyone.S. dry commercial dog food sales were $9.Only two billion as compared to Ough.S. wet dog food sales $2.4 million.

No doubt about it, cereal pet foods will be the most popular style of eating pets, but are kibble pet foods the particular healthiest style of eating pets? With this dilemma, we are not going to take into consideration quality of formula – only processing. Just what exactly processing is concerned to make kibble?

Quoted text message below is from MadeHow.org.

Quoted text message below is from MadeHow.org.

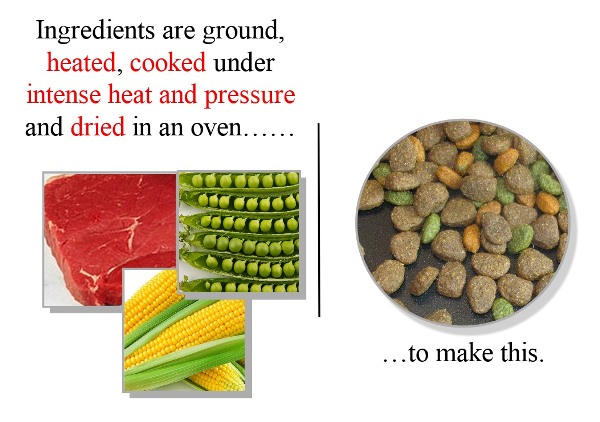

Emphasis added in the following pertaining to heat or preparing of ingredients…

Kibble is a baked dough-type pet food (comparable to funds used to make a hors d’oeuvre or a cracker – along with meat). Because it is produced from dough, all ingredients in a kibble pet food need to be ground very good before mixing. Raw ingredients are “brought alongside one another in a mixer” with increased supplements (mixer is capable of holding 10,000 excess fat or more of components). Next the dough “is heated inside the preconditioner prior to introduction to the actual extruder.” “The extruder, essentially an enormous meat grinder, is how the primary cooking stage for dry extruded dog food products occurs. The actual dough is cooked less than intense heat and pressure as it moves towards the open end with the extruder.” At the end of the extruder this dough is forced by having a “shaping die” and cut into desirable shape. “Kibble is dried in the oven until its water content is low plenty of to make it shelf consistent like a cookie as well as cracker.”

Ingredients are prepared or heated 3 times during the manufacture of kibble family dog foods.

Ingredients are prepared or heated 3 times during the manufacture of kibble family dog foods.

But wait…

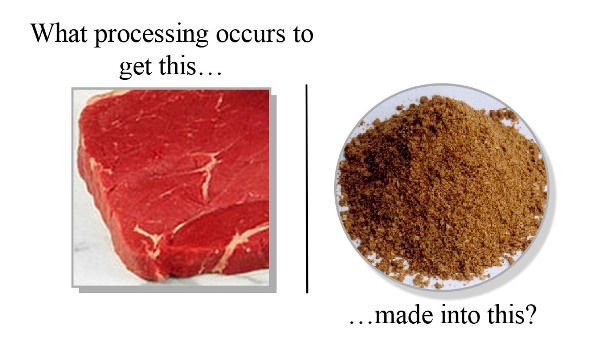

There is more handling to consider; some ingredients are cooked or simply processed prior to arriving at the pet food vegetable such as rendered materials like beef food and chicken mealtime.

Meat meals are commonly used with kibble pet food products. Meat meals are that is generated by finely grinding beef (and often bone), preparing food the material, and removing the remaining moisture within the solids. The solids are dried into a powder like element (above – meat supper). All of this processing transpires before ingredients go through the pet food plant (where by it is cooked just as before in the pet food).

Meat meals are commonly used with kibble pet food products. Meat meals are that is generated by finely grinding beef (and often bone), preparing food the material, and removing the remaining moisture within the solids. The solids are dried into a powder like element (above – meat supper). All of this processing transpires before ingredients go through the pet food plant (where by it is cooked just as before in the pet food).

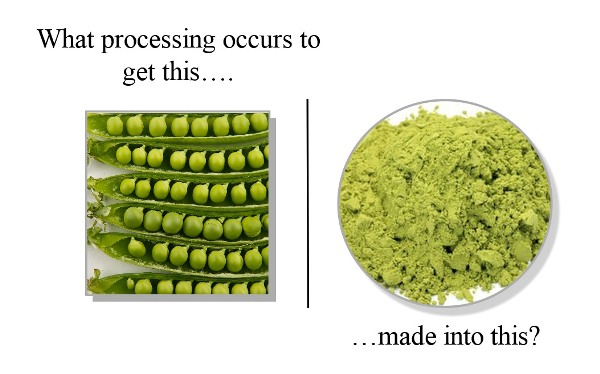

Similar handling can be used for vegetable substances too…

To help kibble maintain its shape after drying, multiple starchy foods are included. One commonly used starch is certainly pea protein (especially in grain free pet ingredients). As you can see in the image above, this compound is processed in a dry powder ahead of its inclusion within the pet food manufacturing process (where it is refined again in the canine).

To help kibble maintain its shape after drying, multiple starchy foods are included. One commonly used starch is certainly pea protein (especially in grain free pet ingredients). As you can see in the image above, this compound is processed in a dry powder ahead of its inclusion within the pet food manufacturing process (where it is refined again in the canine).

So…what is the total? How often are pet food elements cooked during the process connected with kibble manufacturing?

Note: This kind of explanation is for extruded cereal pet foods. Ready kibble pet food are not processed the same as extruded kibble pet foodstuff (but most pet food are made by extrusion). Ready kibble pet food products are processed/cooked less.

If you actually feed kibble, think about the processing involved to make it. Please add some real food to their diet plan each day (replace several kibble with true food). Added various meats can be raw as well as lightly roasted, vegetables lightly cooked.